Thread Rolling

NOTE: MFI Only Offers Thread Rolling as a Secondary Process for our Customers. We Do Not Offer Thread Rolling as a Standalone Service.

What is thread rolling?

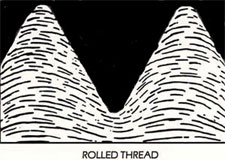

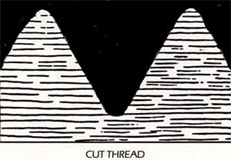

Thread rolling is a mechanical process where threads are cold formed when the part is squeezed between two thread dies on a thread rolling machine. Thread rolling provides for a stronger thread and no loss of material.

What are the primary benefits of thread rolling compared to conventional thread cutting?

- Raw material savings

- 1/4-20 thread pattern produced approximately a 25% savings

- 3/4-16 thread pattern at approximately 16%

- Increased thread strength over machined threads

- Tensile strength increase 10%

- Root hardness increase up to 30%

-

Reduced manufacturing times up to 70%

-

Superior surface smoothness over other techniques

-

Grain Structure retained