Part Examples

Grounding Cable Ferrules

MFI is a leading producer of copper grounding cable ferrules. Our grounding cable ferrules are custom manufactured to standard industry specifications in a wide variety of shrouded and unshrouded versions per customer specifications. Grounding cable ferrules are used to construct grounding cable assemblies used by utility service personnel. We manufacture a wide variety of copper grounding cable ferrules from bar stock, or we can provide a cold-headed blank depending on our customers' requirements. The blanks are cold formed to a net shape, annealed, threaded, marked and tin plated. MFI can produce large volumes or do shorter runs, and all usually with short lead times from date of order. Our sales and engineering team will work with you to evaluate your needs and provide a cost-effective manufacturing solution.

Stud Type, Integral Steel Weld Ring, Semiconductor Bases

MFI is the leading manufacturer of cold formed copper, with steel weld ring, power semiconductor stud bases. Since 1991, MFI has produced thousands of pieces of the DO-2 to DO-8 style stud bases for customers in the United States, United Kingdom, France, Poland, Germany, Morocco, and India. MFI has developed unique production cold forming tools, in depth precision machining expertise, combined with extensive process automation that allows MFI to offer production batch sizes from as small as 100 pieces to batch sizes of over 10,000 pieces on a globally competitive cost basis. Our comprehensive inventory of cold forming tools, assures that our customers never have to pay for tooling when they order standard or specialty power semiconductor stud bases. MFI’s lean manufacturing system assures that order lead times are never longer than 4 weeks from date of order for any type of stud bases. Our sales and engineering personnel will work with you to evaluate your unique requirements and provide a cost effective manufacturing solution.

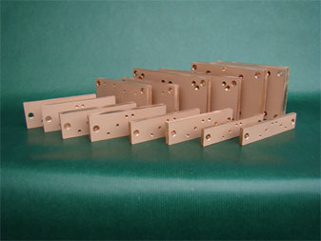

Flat Base, Copper and Steel Power Semiconductor Module Bases

Metal Forming Industries is a leading manufacturer of copper and steel, flat semiconductor module bases that are either air or liquid cooled. Since 1991, MFI has produced flat base plates for customers around the world. MFI has developed unique precision machining expertise that allows us to offer production batch sizes from as small as 100 pieces on a globally competitive cost basis. Our sales and engineering personnel will evaluate your unique requirements and identify procedures to provide a cost effective manufacturing solution. Production orders are typically processed in 4 weeks or less after sample approval. Please contact us today for more information.

Puck Style, Copper Power Semiconductor Housing Bases

MFI is a leading manufacturer of puck style, copper power semiconductor housing bases and lids. Since 1991, MFI has produced thousands of pieces of the housing lids and bases for customers in the United States and United Kingdom. MFI has developed unique in depth copper cold forming and precision copper machining expertise that allows MFI to offer production batch sizes from as small as 100 pieces to batch sizes of over 1,000 pieces on a globally competitive cost basis. Our comprehensive inventory of cold forming tools and machining fixtures, assures that our customers never have to pay for tooling when they order standard or specialty power semiconductor housing bases and lids. MFI’s lean manufacturing system assures that order lead times are never longer than 4 weeks from date of order. Our sales and engineering personnel will work with you to evaluate your unique requirements and provide a cost effective manufacturing solution.

Heavy Duty Thermostat Components (Cups and Guides)

MFI is a leading manufacturer of cold formed and precision machined copper cups and guides used in thermostatic thermal actuator applications. MFI has produced thousands of customer designed, copper thermal actuator, cups and guides for the leading thermal and pressure control device manufacturers. MFI has developed a unique production process that combines the low cost benefits of cold forming with automated specialty precision machining to deliver production batch sizes from as small as 100 pieces to batch sizes of over 10,000 pieces on a globally competitive cost basis. Our use of universal cold forming tools and automated specialty machining, assures that our customers never have to pay for tooling when they order their design specific components. MFI’s lean manufacturing system assures that order lead times are never longer than 4 weeks from date of order for any type of component. Our sales and engineering personnel will work with you to evaluate your unique requirements and provide a cost effective manufacturing solution.